FPC Cutting and Forming 02

FPC Cutting and Forming 02 – Precision Laser Processing

This is advanced laser cutting and forming for flexible printed circuits (FPCs), ideal for high-precision electronics manufacturing, delivering exceptional accuracy and efficiency.

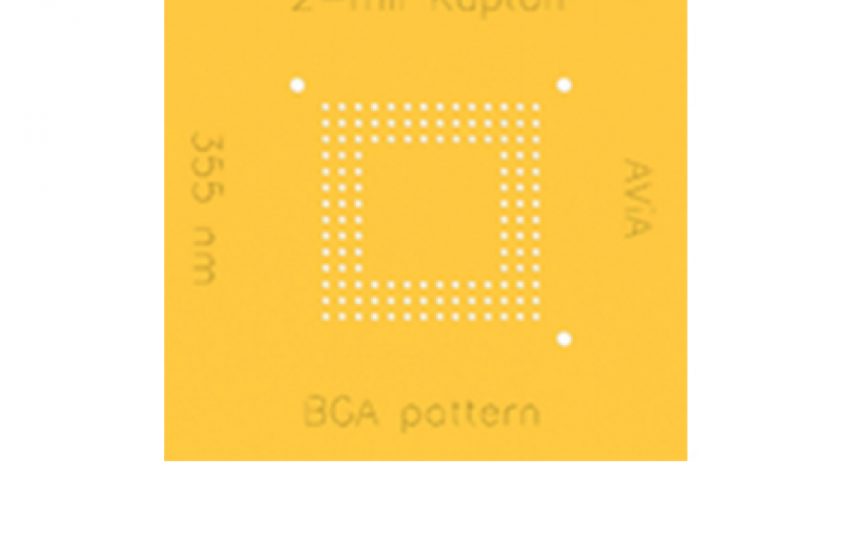

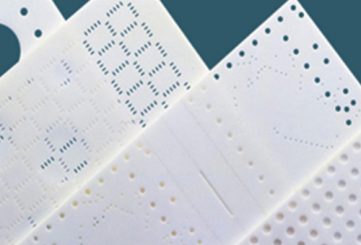

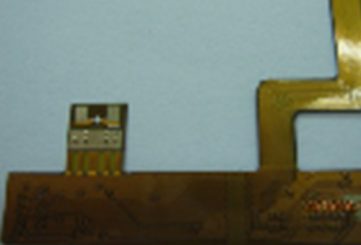

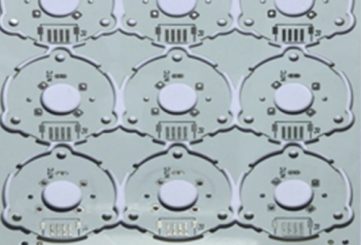

The FPC Cutting and Forming 02 system from AQ-Laser is designed for precision micromachining of flexible printed circuits (FPCs), cover films, and other substrates used in electronics manufacturing. Leveraging state-of-the-art laser technology, this system ensures clean, burr-free cuts and intricate forming with minimal thermal impact. It is tailored for industries requiring high accuracy, such as medical device production, semiconductor manufacturing, and consumer electronics. The system supports a variety of materials, including polyimide (PI), PET, and composite substrates, making it versatile for complex circuit designs and high-density interconnects (HDI). With automated features like precise positioning and cutting, it streamlines production processes while maintaining superior quality.

Key Features:

- Micron-Level Precision: Achieves cutting accuracy of ≤±10μm with seam widths of 15–30μm for intricate, burr-free designs.

- Material Versatility: Processes flexible materials like polyimide (PI), PET, and composite substrates, including FCCL, coverlay, and rigid-flex boards.

- Minimal Thermal Impact: Utilizes advanced UV laser technology to reduce heat-affected zones, ensuring material integrity.

- Automated Processing: Features automatic positioning and focusing systems for high-efficiency production.

- CleanCut Technology: Delivers carbonization-free edges for superior technical cleanliness and reliability.

Certification and Standards:

Meets industry standards for precision electronics manufacturing. Compliant with international quality and safety regulations.

FPC (Flexible Printed Circuit):

- Flexibility: Enables bending and folding for compact designs in medical and electronic devices.

- Lightweight: Thin and low-mass material reduces device weight for enhanced portability.

- High Reliability: Supports complex circuit layouts with excellent thermal and electrical stability.

- Miniaturization: Ideal for high-density, small-scale applications in wearables and implants.

PET (Polyethylene Terephthalate):

- Chemical Resistance: Withstands exposure to medical and industrial chemicals for reliable performance.

- Flexibility and Strength: Combines durability with flexibility for use in flexible displays and sensors.

- Cost-Effective: Economical material for large-scale production of medical and electronic components.

- Transparency: Ideal for optical applications in diagnostic and laboratory devices.

PI (Polyimide):

- High Thermal Stability: Withstands temperatures up to 400°C, perfect for high-heat medical and industrial applications.

- Excellent Dielectric Properties: Ensures reliable insulation in flexible circuits and sensors.

- Chemical Resistance: Resists harsh chemicals, enhancing longevity in medical environments.

- Flexibility: Supports intricate designs in compact, high-performance electronic devices.

Copper Foil:

- Superior Conductivity: Offers excellent electrical conductivity for high-performance circuits and probes.

- Corrosion Resistance: Ensures durability in medical and industrial environments with minimal degradation.

- Thin and Lightweight: Enables precision applications in electronics and medical sensors.

- Malleability: Easily shaped for intricate designs in circuit boards and conductive components.

Aluminum Foil:

- Lightweight: Low density reduces overall weight in medical and industrial applications.

- Corrosion Resistance: Resists oxidation, ensuring durability in harsh environments.

- High Conductivity: Supports efficient electrical and thermal performance in electronic components.

- Cost-Effective: Affordable material for large-scale production of precision parts.

- Precision cutting and forming of FPCs for medical devices, wearables, and consumer electronics.

- Contour cutting, drilling, and marking of flexible and rigid-flex circuit boards.

- Processing of cover films, adhesives, and EMI shielding films for compact, high-performance electronics.

- Ideal for high-density interconnect (HDI) designs and complex circuit geometries in telecommunications and automotive industries.

- Laser Type: High-performance UV laser

- Cutting Accuracy: ≤±10μm

- Cutting Seam Width: 15–30μm

- Material Compatibility: Polyimide (PI), PET, FCCL, coverlay, rigid-flex boards

- Processing Capabilities: Contour cutting, drilling, marking, and forming

- Automation: Automatic positioning, focusing, and feeding systems

- Supported Formats: Gerber, DXF, DWG, SVG, and other 2D CAD formats