Sapphire Molding

Sapphire Molding – Precision Laser Solution

This is an advanced laser system for molding sapphire substrates, ideal for medical and optical applications, delivering unmatched precision.

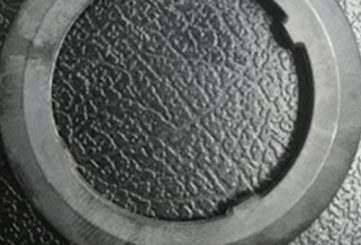

The Sapphire Molding system from AQ-Laser is a cutting-edge laser processing solution designed for high-precision molding and micromachining of sapphire substrates, renowned for their exceptional hardness and optical clarity. Tailored for industries such as medical device manufacturing, optoelectronics, and high-precision electronics, this system ensures clean, burr-free molding with minimal thermal impact. Optimized for sapphire’s unique properties, it enables intricate designs critical for applications like optical lenses, medical implants, and high-frequency components. Equipped with automated features such as precise positioning and focusing, it ensures efficient, high-quality production for advanced components.

Key Features:

- High-Precision Molding: Achieves molding accuracy of ≤±10μm for intricate, burr-free designs.

- Material Optimization: Processes sapphire substrates with exceptional hardness and optical transparency.

- Low Thermal Impact: Advanced UV laser technology minimizes heat-affected zones, preserving material integrity.

- Automated Efficiency: Includes automatic positioning, focusing, and feeding systems for streamlined production.

- CleanCut Technology: Ensures carbonization-free edges, enhancing technical cleanliness and reliability.

- Scratch Resistance: Supports sapphire’s superior durability and resistance to scratches for long-lasting components.

Certification and Standards:

Certified to ISO9001 and IATF16949 standards, ensuring consistent quality for medical and optoelectronic applications. Compliant with CE marking and RoHS directives for safety and environmental sustainability.

Primary Material:

- High-purity sapphire (Al₂O₃)

High-purity sapphire (Al₂O₃) is a crystalline material renowned for its exceptional hardness, optical transparency, and thermal stability. Ideal for medical implants, optical components, and high-frequency electronics, it ensures durability and precision in demanding applications.

Alternative Materials:

- Alumina

- Zirconia

- Silicon nitride

- other high-hardness ceramics (optional based on application requirements).

- High-precision molding of sapphire substrates for medical implants and optical components.

- Cutting, drilling, and shaping for high-performance lenses, RF modules, and optoelectronic devices.

- Processing of sapphire for semiconductor packaging and telecommunications equipment.

- Suitable for high-density interconnect (HDI) designs in aerospace and medical applications.

- Laser Type: High-performance UV laser

- Molding Accuracy: ≤±10μm

- Molding Seam Width: 15–30μm

- Material Compatibility: Sapphire substrates

- Processing Capabilities: Molding, cutting, drilling, and marking

- Automation: Automatic positioning, focusing, and feeding systems

- Supported Formats: Gerber, DXF, DWG, SVG, and other 2D CAD formats