High Precision products

0 itemsCustom Manufacturing of High-Precision Components According to Customer Specifications

We offer precision manufacturing of high-accuracy components for medical and industrial applications, fully based on customer requirements. All parts are produced according to provided drawings, CAD models, or detailed technical specifications.

Our flexible manufacturing process supports a wide range of custom geometries, critical tolerances, materials, and surface finishes. We work closely with our clients to ensure their specific application needs are met at every stage — from prototyping to series production.

Read more about Application and Key Features…

Application:

High-precision components are essential in a variety of medical and engineering fields that demand exact tolerances and repeatable performance. Typical applications include:

- Micro-mechanical parts for medical devices

- Components for surgical tools and diagnostic equipment

- Precision parts for catheter systems

- Custom inserts, holders, and structural elements for lab setups

- R&D components for clinical testing and prototyping

To discuss your project or request a quote, please contact us with your drawings or technical documentation.

Key capabilities include:

- Manufacturing based on customer drawings and 3D CAD models

- Tight tolerances and high repeatability

- Support for a wide range of metals and polymers

- Micro-machining, laser cutting, drilling, and marking

- Prototyping and small to medium batch production

- Post-processing and surface finishing options upon request

Each order is treated as a custom project, ensuring compliance with your technical requirements and quality standards. Our facility is equipped for contract manufacturing and OEM supply with full documentation and traceability.

- Stent cutting

- Snake bones

- Hybotube (hipodermic tube)

- Needles

- Surgical instruments

- Medical Devices

- Stainless Steel Cutting and Forming

- Substrates for Electronics Manufacturing

- Hard and Brittle Devices

- Non-Metallic Devices

- Marking and Welding

-

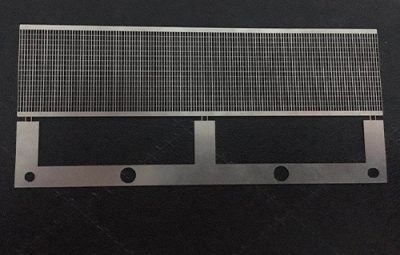

Precision Thin Steel Vacuum Adsorption & Honeycomb Fixture

The Precision Thin Steel Vacuum Adsorption & Honeycomb Fixture is a high-precision laser-cut component designed for use in various industrial and medical applications. -

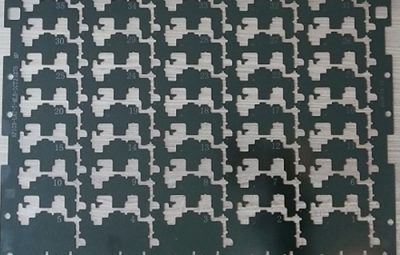

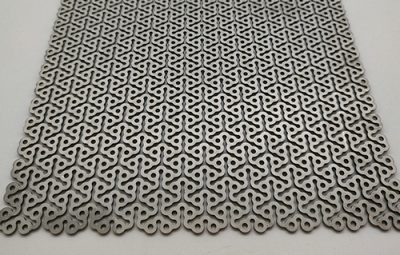

Stainless Steel Screen Cutting and Forming

The Stainless Steel Screen Cutting and Forming is a high-precision laser-cut component designed for use in various industrial and decorative applications. -

WT0.15 Stainless Steel Components

The WT0.15 Stainless Steel Cutting and Forming is a high-precision laser-cut component designed for use in various industrial and medical applications. -

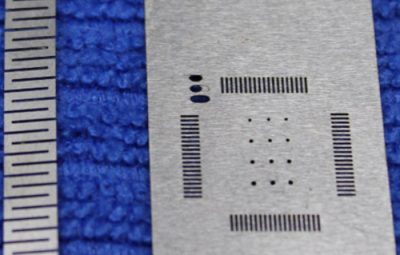

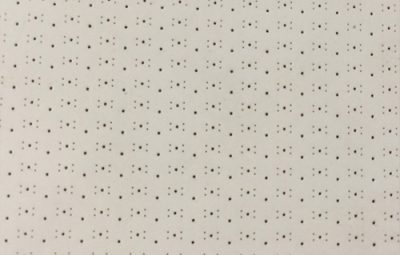

WT0.06mm-0.2mm Electroplated Furnace Stainless Steel Sheet Cutting & Scribing & Marking

The WT0.06mm-0.2mm Electroplated Furnace Stainless Steel Sheet Cutting & Scribing & Marking is a high-precision laser micromachining solution designed for creating intricate and durable components for electroplated furnace applications. -

WT0.2mm Stainless Steel Blade Cutting and Forming

The WT0.2mm Stainless Steel Blade Cutting and Forming is a high-precision laser-cut component designed for use in industrial and medical applications. -

WT0.2mm L1400mm W600mm Stainless Steel Decorative Strip Cutting and Forming

The WT0.2mm L1400mm W600mm Stainless Steel Decorative Strip Cutting and Forming is a high-precision laser-cut component designed for use in decorative and industrial applications. -

WT0.2mm Stencil Cut to Shape

The WT0.2mm Stencil Cut to Shape is a high-precision laser-cut component designed for use in various industrial and medical applications. -

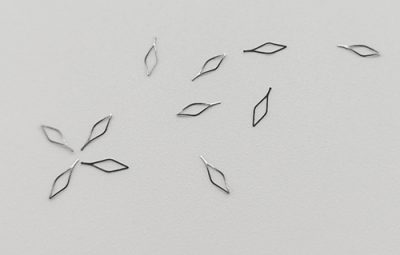

L1.2mm Bracket Rod

The L1.2mm Bracket Rod Forming is a high-precision laser-cut medical component designed for use in various medical applications. -

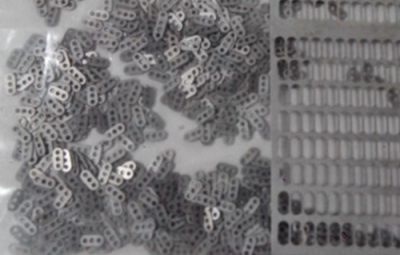

SUS304 Endoscope Clip

The SUS304 Endoscope Clip is a high-precision laser-cut medical component designed for use in endoscopic procedures. -

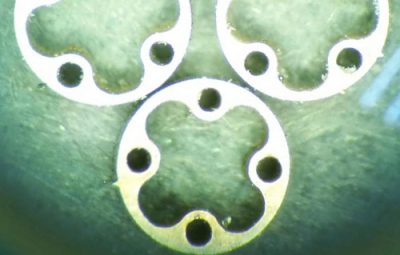

Ceramic Microscope Component

The Ceramic Microscope Machining is a high-precision laser micromachining solution designed for creating intricate and durable components for microscopes and other medical devices. -

Nickel Titanium Electrode

The Nickel Titanium Electrode is a high-precision laser-cut medical component designed for use in advanced medical applications. -

Various Alloy Microstructure Components

The Various Alloy Microstructure Forming is a high-precision laser micromachining solution designed for creating intricate and durable microstructures on various alloy materials. -

CT Tungsten Steel Electrode

The CT Tungsten Steel Electrode is a high-precision laser-cut medical component designed for use in advanced medical applications. -

WT 0.8mm Titanium Alloy Cranial Fixation Sheet

The WT 0.8mm Titanium Alloy Cranial Fixation Sheet is a high-precision laser-cut medical component designed for cranial fixation applications. -

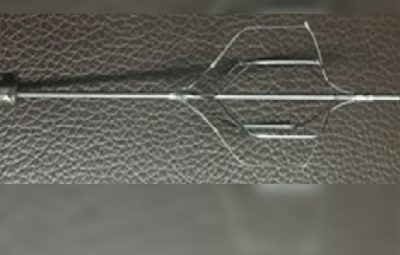

Welding the Head of the Stone Basket

The Welding the Head of the Stone Basket is a high-precision laser welding solution designed for creating strong and seamless welds on the head of stone baskets. -

Surgical Instrument Join and Tube Body Welding

The Surgical Instrument Join and Tube Body Welding is a high-precision laser welding solution designed for creating strong and seamless welds on surgical instruments and tube bodies. -

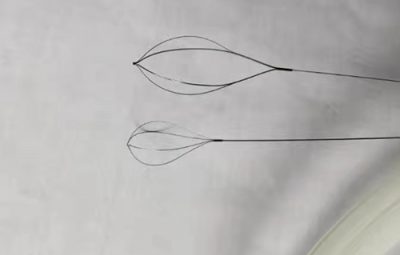

Ni-Ti Venous Filter Shape Welding

The Ni-Ti Venous Filter Shape Welding is a high-precision laser welding solution designed for creating strong and seamless welds on nickel-titanium (Ni-Ti) venous filters. -

Urinary Cobra Bone Automatic Compression & Threading & Welding Samples

The Urinary Cobra Bone Automatic Compression & Threading & Welding Samples is a high-precision laser welding solution designed for creating strong and seamless welds on urinary cobra bone components.