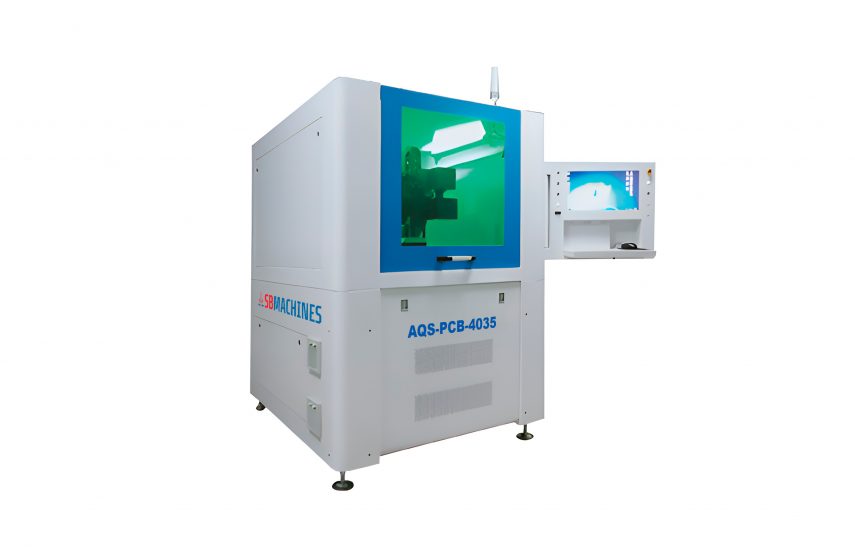

AQS-PCB-4035 UV laser cutting machine for precision PCB

AQS-PCB-4035 UV Laser Cutting Machine for Precision PCB – High-precision UV micromachining for advanced PCB substrates

The AQS-PCB-4035 is an ultraviolet laser cutting system designed especially for delicate and precise processing of PCB and related materials. It performs tasks such as PCB splitting, drilling, slotting, cover film window opening, and flex-rigid board trimming. The machine’s architecture combines reliable mechanical systems, precise UV laser control, and optimized optics to deliver superior microfabrication performance.

Its compact yet robust construction makes it suitable for electronics production lines and cleanroom environments. The control system and expansion capability offer flexibility for industries focused on microelectronics, FPC, hybrid circuits, and other high-precision PCB applications.

Scope of application

This machine is perfect for industries producing PCBs, FPCs, MEMS modules, hybrid circuits, sensors, and fine electronics components where precision is paramount. It handles a wide spectrum of substrate materials and allows multiple microprocessing operations on a unified platform.

Advantages:

- Supports processing of materials like copper foil, aluminum foil, composite, ceramic, PET, PI, glass fiber

- Capable of performing cutting, drilling, slotting, scribing, and film window cutting

- Designed for both prototype fabrication and high-throughput electronics production

- Maintains high accuracy even under varied production conditions

High finishing

Thanks to its UV laser technology, the AQS-PCB-4035 achieves extremely fine cuts with minimal thermal impact. This ensures superior surface quality, reduces defects, and significantly lowers the burden of post-processing.

Advantages:

- Cutting seam width: 15 ~ 30 μm

- Machining accuracy: ≤ ±10 μm

- Smooth cuts with minimal burrs and very small heat-affected zones

- Fine feature capability down to ~50 μm in size

Strong adaptability

The AQS-PCB-4035 is designed to work with a broad range of substrates and surface conditions. It supports processing of copper, aluminum, ceramic, composites, flexible films, and coated or pretreated materials, all without degrading cut quality. The system is built with high-precision direct drive motion stages, sealed axes, and offers optional modules like automatic loading/unloading, vision-based alignment, vacuum holding fixtures, and dust/smoke extraction systems.

Its control firmware also allows for flexible workflow adaptation, such as multi-pass cutting, micro-routing, blind scribing, and customizable patterns according to production needs.

Flexible design

The machine is engineered with modularity and user-centric customization in mind. Users can select tailored combinations of software and hardware modules to match their process requirements. It also supports smart production management and innovative system-level enhancements.

Advantages:

- Flexible software/hardware combinations and customizable function sets

- Compact, ergonomic design suitable for electronics manufacturing environments

- Open control architecture with intuitive user interface for UV laser micromachining

Technical certification

The AQS-PCB-4035 is manufactured under internationally recognized quality standards and undergoes stringent inspection and calibration procedures. The system is certified under ISO9001 and IATF16949, ensuring consistent precision, reliability, and traceability throughout its operational lifecycle.

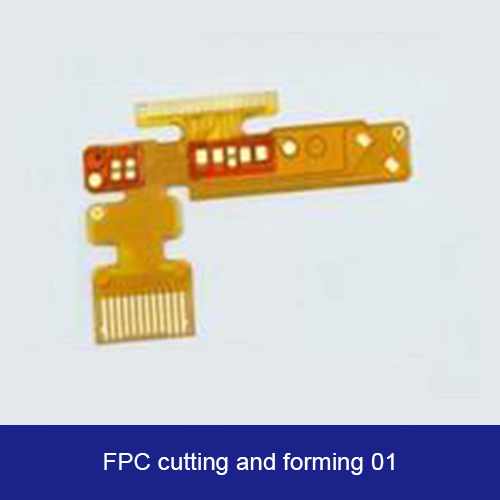

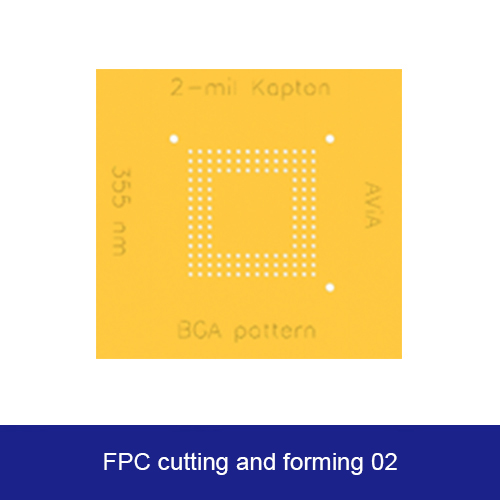

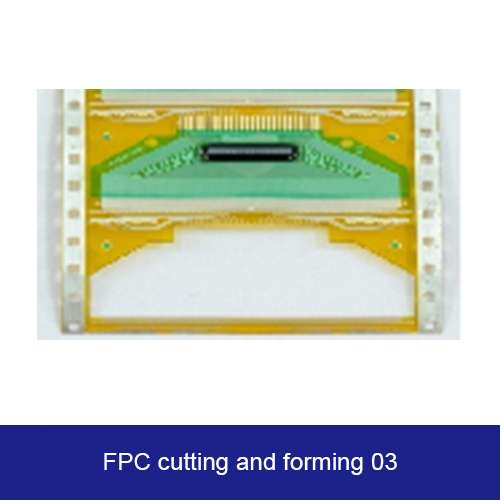

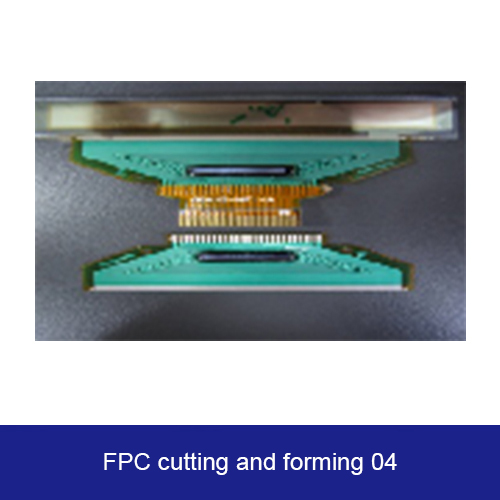

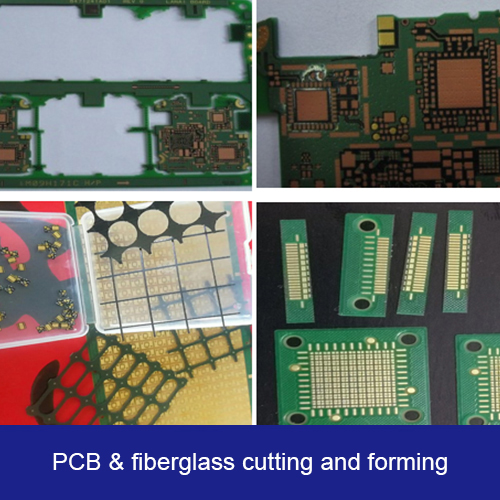

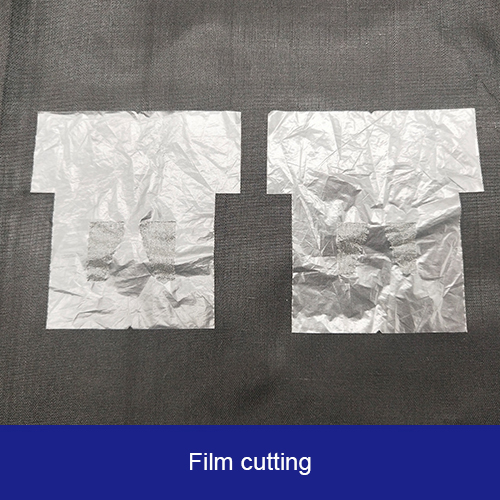

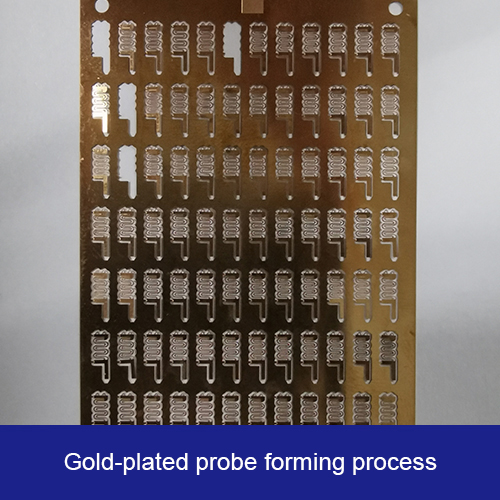

Sample Display

Processing Materials:

- FPC (Flexible Printed Circuit)

- Flexibility: Enables bending and folding for compact designs in medical and electronic devices.

- Lightweight: Thin and low-mass material reduces device weight for enhanced portability.

- High Reliability: Supports complex circuit layouts with excellent thermal and electrical stability.

- Miniaturization: Ideal for high-density, small-scale applications in wearables and implants.

- PCB (Printed Circuit Board) PCB aluminum substrate is a composite material consisting of a thin layer of dielectric insulation bonded to an aluminum base, offering excellent heat dissipation, mechanical stability, and dimensional accuracy for electronic circuit applications.

- PET (Polyethylene Terephthalate)

- Chemical Resistance: Withstands exposure to medical and industrial chemicals for reliable performance.

- Flexibility and Strength: Combines durability with flexibility for use in flexible displays and sensors.

- Cost-Effective: Economical material for large-scale production of medical and electronic components.

- Transparency: Ideal for optical applications in diagnostic and laboratory devices.

- PI (Polyimide)

- High Thermal Stability: Withstands temperatures up to 400°C, perfect for high-heat medical and industrial applications.

- Excellent Dielectric Properties: Ensures reliable insulation in flexible circuits and sensors.

- Chemical Resistance: Resists harsh chemicals, enhancing longevity in medical environments.

- Flexibility: Supports intricate designs in compact, high-performance electronic devices.

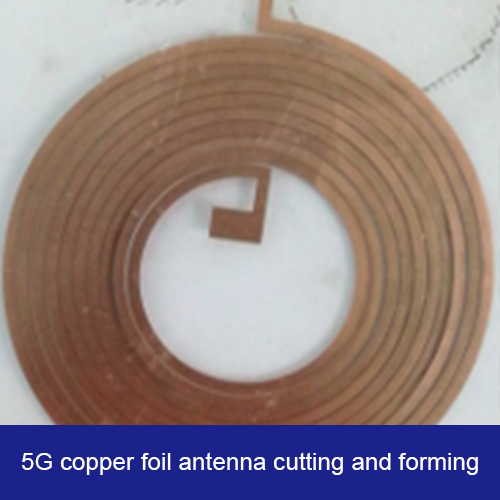

- Copper foil

- Superior Conductivity: Offers excellent electrical conductivity for high-performance circuits and probes.

- Corrosion Resistance: Ensures durability in medical and industrial environments with minimal degradation.

- Thin and Lightweight: Enables precision applications in electronics and medical sensors.

- Malleability: Easily shaped for intricate designs in circuit boards and conductive components.

- Aluminum foil

- Lightweight: Low density reduces overall weight in medical and industrial applications.

- Corrosion Resistance: Resists oxidation, ensuring durability in harsh environments.

- High Conductivity: Supports efficient electrical and thermal performance in electronic components.

- Cost-Effective: Affordable material for large-scale production of precision parts.

- Carbon fiber

- High Strength-to-Weight Ratio: Provides exceptional strength while remaining lightweight for medical and industrial use.

- Corrosion Resistance: Withstands harsh environments, ideal for durable medical implants and tools.

- Rigidity: Ensures structural stability in precision components like surgical instruments.

- Thermal Stability: Maintains performance under high temperatures in demanding applications.

- Glass fiber

- High Mechanical Strength: Provides excellent tensile strength and rigidity, ensuring durable substrates for demanding electronic applications.

- Thermal Resistance: Withstands high temperatures, making it ideal for high-performance PCBs and medical device components.

- Electrical Insulation: Offers superior dielectric properties, preventing unwanted electrical conductivity in circuit boards.

- Dimensional Stability: Maintains shape and structure under stress, supporting precise manufacturing of complex designs.

- Lightweight: Contributes to reduced overall weight of electronic assemblies, enhancing portability in devices like wearables.

- Chemical Resistance: Resists corrosion from chemicals and environmental factors, ensuring long-term reliability.

- Composite materials

- Tailored Properties: Combines materials for customized strength, flexibility, and durability in medical devices.

- Lightweight: Reduces weight while maintaining structural integrity for portable equipment.

- Corrosion Resistance: Enhances longevity in medical and industrial environments.

- Versatility: Supports complex designs for advanced applications in electronics and implants.

- Ceramic and others

Laser Specifications:

- UV Fiber Laser with wavelength 355±5nm

- Power Options: 10W & 15W (nanosecond and picosecond)

- Cutting Seam Width: 15~30μm

- Material Wall Thickness: 0~1.0±0.02mm

Scope of Use

- Laser splitting and drilling of PCBs

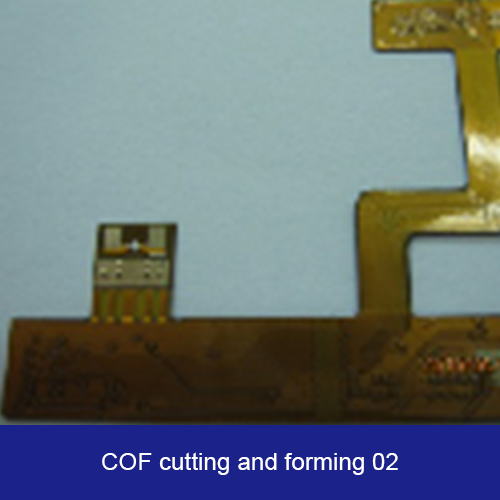

- Processing camera and fingerprint recognition modules

- Cover film window opening, flex-rigid board uncovering, and trimming

- Scribing silicon steel sheets and ceramics

- Laser cutting and forming of ultra-thin composite materials, including:

- Copper and aluminum foil

- Carbon and glass fiber

- PET and PI

Processing Capabilities

- High machining accuracy: ≤±10μm

- Smooth incision with minimal heat-affected zone and no burrs

- Minimum product size: 50μm

Industries Served

- Electronics manufacturing

- Semiconductor industry

- Flexible and rigid PCB production

Performance and Efficiency

Maximum Operating Speeds:

- X, Y1, Y2 Axes: 500mm/s

- Z Axis: 50mm/s

Positioning Accuracy:

- ±3μm (X, Y1, Y2, Z)

Repeatability:

- ±1μm (X, Y1, Y2, Z)

Advanced Features

- Self-developed XY motion platform and split-type fixed gantry design

- Optional automatic loading and unloading system

- Bilateral CCD visual positioning with pre-scan and automatic target alignment

- Precision vacuum adsorption fixture and integrated dust removal piping system

Certified Quality

- ISO9001

- IATF16949

Design Excellence

- Compact, ergonomic design

- Flexible combination of hardware and software for personalized production

- Intelligent management with an intuitive user interface

- Self-developed 2D and 2.5D CAM software system