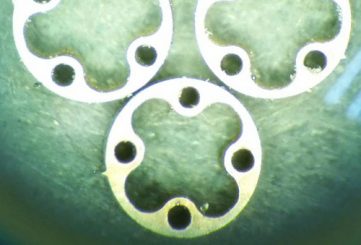

Braces Plastic Component

Braces Plastic Component – Precision Orthodontic Parts for Dental Applications

The Braces Plastic Component is a high-precision laser-cut part designed for orthodontic applications, particularly in the production of dental braces and aligners. Manufactured using advanced five-axis laser cutting technology, this component ensures exceptional accuracy, efficiency, and a burr-free finish with minimal thermal distortion. Crafted from medical-grade plastics such as polycarbonate, polypropylene, and PET, it offers excellent biocompatibility, durability, and flexibility. The laser-cut design provides smooth, sealed edges and intricate geometries, ensuring patient comfort and reliable performance in dental treatments. Ideal for modern orthodontic devices, this component meets the stringent standards of contemporary healthcare.

Key Features:

- Ultra-Precise Cutting: Seam width of 18–30 µm with machining accuracy of ≤±10 µm for intricate designs.

- Burr-Free Edges: Smooth, sealed surfaces enhance patient comfort and reduce irritation.

- Material Versatility: Compatible with medical-grade plastics like polycarbonate, polypropylene, and PET.

- Minimal Thermal Distortion: Laser technology ensures clean cuts with no material degradation.

- Automated Production: Continuous feeding system ensures high efficiency and consistent quality.

- Biocompatibility: Meets standards for safe interaction with human tissues in dental applications.

Certification and Standards:

Certified under ISO 9001, ISO 13485, and ISO 10993 for quality management and biocompatibility. Compliant with CE and FDA regulations for medical device safety and efficacy.

Plastic Materials for Braces:

- Suitable for cutting various types of plastics used in the manufacturing of orthodontic devices, including medical-grade plastics, polycarbonate, and other polymer materials.

- Orthodontic Devices: Essential for precision components in dental braces and aligners.

- Dental Aligners: Used in clear aligner systems for customized orthodontic treatments.

- Medical Device Manufacturing: Incorporated in the production of high-precision dental instruments.

- Prosthetic Dentistry: Supports fabrication of custom dental prosthetics and retainers.

- Diagnostic Equipment: Used in dental imaging and treatment planning systems.

- Material: Polycarbonate, Polypropylene, PET

- Cutting Seam Width: 18–30 µm

- Machining Accuracy: ≤±10 µm

- Surface Roughness: Ra <0.2 µm

- Manufacturing Process: Five-axis laser cutting with automated feeding

- Operating Temperature: -20°C to 150°C, suitable for sterilization

- Degradation: Non-degradable, designed for long-term stability