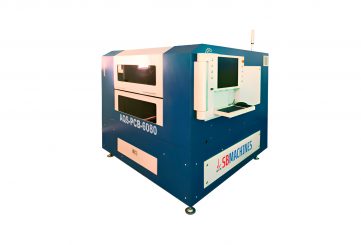

AQS-ME-6045 Laser cutting machine for 2D medical equipment

AQS-ME-6045 Laser Cutting Machine for 2D Medical Equipment – High-Precision Sheet Micromachiner

The AQS-ME-6045 is engineered for ultra-precise cutting of 2D medical components, combining micromachining performance with stability and consistency. It handles both planar and curved profiles with tight tolerances, making it ideal for manufacturing sheets, connectors, electrode plates and fixation components in the medical device industry.

With its dual-drive direct motion system and optimized optical path, the AQS-ME-6045 delivers fine kerf widths and smooth edges, while maintaining throughput suitable for production environments.

Scope of application

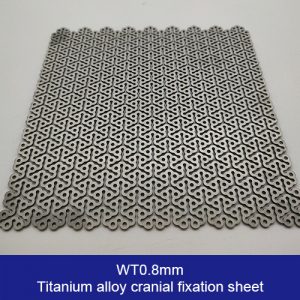

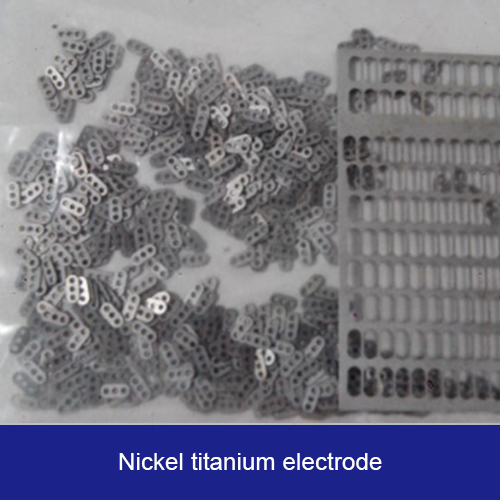

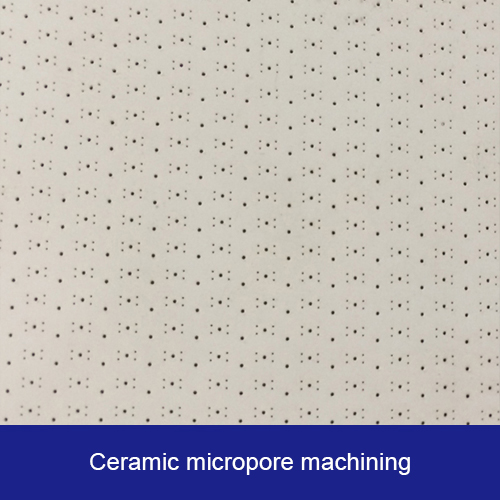

This machine is tailored for micromachining of medical device parts such as cranial fixation sheets, connecting plates, electrode sheets, and other 2D components. It is especially valuable where high accuracy, minimal thermal damage, and reliable consistency are required.

Advantages include:

- Kerf width in the range of ~15–30 µm (depending on material and parameters)

- High processing precision: ≤ ±10 µm alignment and repeatability

- Burr-free edges, smooth cuts, and minimal post-processing

- Efficient operation enabled by direct-drive dual-motor motion

- Capability to cut through a single layer of thin medical-grade materials in one pass

High finishing

The AQS-ME-6045 is built for superior cut quality. Its optical focusing and beam shaping, combined with stable motion, produce very fine edges with minimal roughness or dross.

Key benefits:

- Very narrow, precise kerf with minimal material loss

- Clean cutting surfaces that require little or no secondary finishing

- Smooth edges without tearing or chipping

Strong adaptability

The system supports multiple micromachining functions — not limited to cutting, it also accommodates drilling, slotting, scribing, and fine feature structuring. This versatility enables one platform to handle multiple process steps. It is compatible with various biocompatible and implant-grade materials, such as stainless steel (304 / 316L), NiTi alloys, L605, Li, Mg, Al, Cu, Fe, ceramics, and more. The motion and mechanical structure allow processing of flat, curved, or slightly contoured parts. Optional modules for dual-station loading, machine vision, automatic feed/unload, and dynamic processing monitoring further expand adaptability.

Flexible design

The AQS-ME-6045 uses a compact, modular architecture to ease integration into medical device production lines or cleanroom labs. Its components — optical path, laser head, motion axes, and control units — are organized for convenient accessibility and maintainability.

Advantages include:

- Modular layout for scalable configuration

- Easy access to components for maintenance or trade-in

- Option to add or upgrade modules, such as dual stations or vision systems

Technical certification

The AQS-ME-6045 is manufactured to comply with industry standards for precision laser cutting equipment, incorporating safety, electromagnetic compatibility (EMC), and quality certifications suitable for regulated sectors like medical devices, electronics, and aerospace.

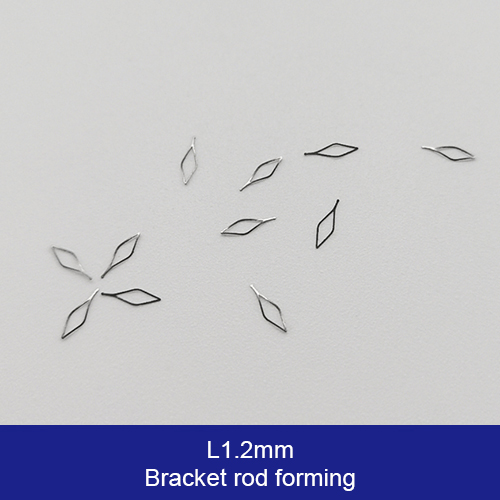

Sample display

Processing Materials:

- Stainless Steel

Medical-grade SUS304 stainless steel (austenitic chromium-nickel alloy), offering excellent corrosion resistance and mechanical properties.

- Biocompatibility: Low risk of allergic reactions or toxicity, ideal for direct tissue contact in medical procedures.

- Mechanical Properties: High tensile strength (approximately 505 MPa) and elongation (up to 40%), providing flexibility without brittleness.

- Surface Finish: Laser-machined for smooth, burr-free edges, reducing the potential for tissue trauma or contamination.

- Thermal Stability: Maintains integrity across a wide temperature range, suitable for sterilization processes like autoclaving.

- Nickel-Titanium alloy: Nitinol (NiTi), a nickel-titanium alloy, is renowned for its superelasticity and shape memory, making it a game-changer in medical applications. With a tensile strength of up to 1200 MPa and elastic modulus of 40–75 GPa, nitinol excels in demanding environments.

- Cobalt-Chromium Alloys (L605): Cobalt-Chromium Alloys (L605) are medical-grade materials valued for their exceptional strength, corrosion resistance, and biocompatibility. With tensile strength ranging from 800–1500 MPa and hardness of 300–550 HV, they ensure durability in demanding medical applications. Ideal for implants and surgical tools, they support direct tissue contact with minimal reaction. Laser-machined surfaces provide smooth, burr-free finishes, enhancing performance in sensitive procedures.

- Magnesium alloy: Magnesium, a lightweight (1.74 g/cm³) and biodegradable metal, is ideal for temporary medical implants like stents and orthopedic screws. Alloys such as WE43 or JDBM offer tensile strength (200–420 MPa) and controlled degradation (6–24 months), safely dissolving into non-toxic byproducts (Mg²⁺ ions). Its biocompatibility (ISO 10993) and ability to support tissue regeneration make it suitable for cardiovascular and bone repair applications. Magnesium’s elastic modulus closely matches bone, minimizing stress shielding in orthopedic uses.

- Lithium (Li): A lightweight, highly reactive metal used in medical devices like batteries for implants. Its high energy density and biocompatibility make it ideal for powering pacemakers and neurostimulators.

- Aluminum Aluminum Alloys are lightweight, medical-grade materials valued for their excellent corrosion resistance and high strength-to-weight ratio. With tensile strength typically ranging from 200–600 MPa and good ductility, they offer durability for medical and industrial applications. Their biocompatibility supports use in non-implantable devices and components. Laser-machined for smooth, burr-free surfaces, they minimize contamination risks and ensure compatibility with sterilization processes.

- Copper A conductive, antimicrobial metal used in medical equipment and coatings. Its excellent electrical conductivity and natural resistance to bacteria enhance device functionality and hygiene.

- Titanium alloys: Titanium Alloys are medical-grade materials prized for their high strength-to-weight ratio, excellent corrosion resistance, and superior biocompatibility. With tensile strength ranging from 900–1200 MPa and good ductility, they provide durability and flexibility for demanding medical applications. Their bio-inert properties make them ideal for implants and instruments requiring direct tissue contact. Laser-machined surfaces ensure smooth, burr-free finishes, minimizing tissue irritation in sensitive procedures.

- Iron (Fe): A strong, durable metal used in some surgical instruments and structural components. Its high strength and cost-effectiveness make it suitable for non-implantable medical tools.

- Ceramic:

A biocompatible, wear-resistant material used in orthopedic and dental implants. Its hardness, corrosion resistance, and bioinert properties ensure long-term stability and tissue compatibility.

Laser Specifications:

- Fiber-Optic Laser

- Wavelength: 1030~1070±10nm

- Power Options:

- 100W

- 200W

- 250W

- 300W

- 500W

- 1000W

- QCW150W

Cutting Parameters:

- Wall Thickness: 0~2.0±0.02mm

- Cutting Seam Width: 15~30μm

Scope of Use

Laser micromachining of flat and curved medical instruments, including:

- Cranial fixation sheets

- Connecting sheets

- Electrode sheets

Processing Capabilities

- Cutting, drilling, slotting, and scribing

- Precision cutting with burr-free and smooth edges

- Direct-drive dual-drive system for efficient single-layer material cutting

Industries Served

- Endoscopic medical equipment manufacturing

- Precision medical device production

Performance and Efficiency

Maximum Operating Speeds:

- X, Y1, Y2 Axes: 500mm/s

- Z Axis: 50mm/s

Positioning Accuracy:

- ±3μm (X, Y1, Y2)

- ±5μm (Z)

Repeatability:

- ±1μm (X, Y1, Y2)

- ±3μm (Z)

Precision and Flexibility

- Processing Range: 450mm × 600mm

- Long & short focal length laser cutting heads with self-developed sharp & flat nose

- Compatible with commercially available laser cutting heads

Advanced Features

- Double station and machine vision positioning options

- Material receiving and closed blanking system

- Automatic loading and unloading system

- Real-time processing dynamic monitoring

Certified Quality

- ISO9001

- ISO13485

User-Centric Design

- Ergonomic and compact design

- Flexible software and hardware configuration for customized functionality

- Intuitive interface for easy operation and intelligent production management