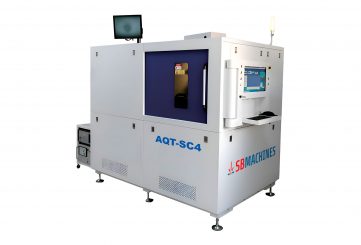

AQT-SE Five-axis laser cutting machine for surgical equipment

AQT-SE Five-axis Laser Cutting Machine for Surgical Equipment – Ultimate Precision Tube Machining

The AQT-SE Five-axis Laser Cutting Machine is engineered specifically for manufacturing surgical equipment components with unrivalled precision and surface quality. Using five-axis motion control, this machine excels in processing complex thin-walled tubes and small surgical parts like endoscopes, staplers, soft drills and nasal drills. Its advanced laser source and rigid structure ensure minimal thermal distortion, high repeatability and clean edge quality.

Capable of handling a variety of metals and surgical-grade alloys, the AQT-SE is ideal for high-volume, high-precision production runs. The integrated automation and control systems permit fast changeovers and exact operations, minimizing waste and maximizing yield.

Scope of application

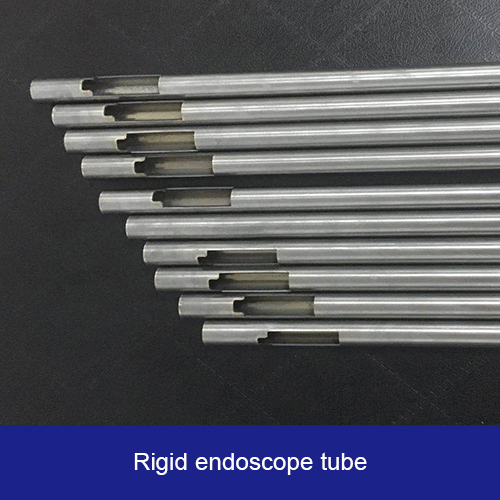

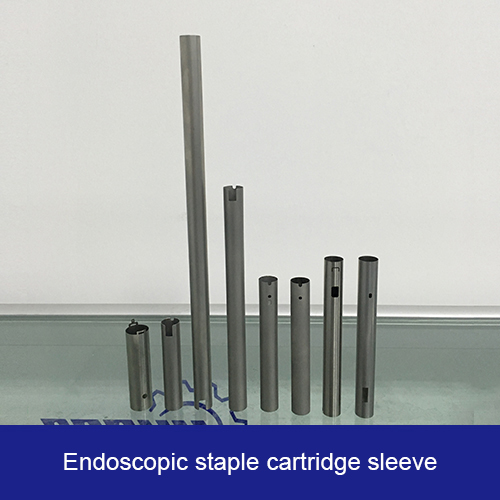

This machine is suited for producing rigid endoscopes, ultrasonic knives, staplers, soft drills, puncture needles, nasal drills and other small surgical-instrument components requiring both geometric complexity and stringent surface finish. It supports tube sizes typical for such medical tools and materials that comply with surgical standards.

Advantages:

High throughput with consistent quality, reducing scrap and downtime.

- Precision machining of curved and spiral geometries; multi-axis control allows cutting at various angles without repositioning the workpiece.

- Clean, burr-free cutting that reduces or eliminates need for secondary finishing.

- High throughput with consistent quality, reducing scrap and downtime.

High finishing

The AQT-SE delivers surfaces with extremely smooth finishes thanks to its precise laser optics, stable beam delivery, and cooling / thermal management system. Tight control over the laser parameters produces minimal heat-affected zones, ensuring fine edge definition and minimal discoloration or distortion.

- Near mirror-like surface finish on inner and outer tube walls.

- Minimal taper and kerf variation across the part.

- Reduced post-processing (polishing / electropolishing / mechanical finishing).

Strong adaptability

The AQT-SE adapts well to a range of materials used in surgical instruments, including various stainless steels, titanium alloys, NiTi (nitinol), cobalt-chromium, and other biocompatible metals. Its controls allow for adjusting cut parameters for small tubes, sharp bends, and delicate features without compromising on accuracy.

It also handles various tube diameters and wall thicknesses, making it suited for both highly specialized small-batch instruments as well as scaled up manufacturing. Whether it’s hollow tubes, curved endoscopic parts, or solid fittings, the flexibility of five-axis machining accommodates runs of varied complexity.

Flexible design

The mechanical and software architecture of the AQT-SE is built for adaptability. It allows modular fixtures and tooling for different tube geometries, automated loading and unloading, and programmable head paths for complex angled cuts.

- Modular fixtures for different tube outer diameters and profiles.

- Configurable cutting head angles & multiaxis trajectories without mechanical repositioning.

- Easy integration with automated feeding systems and quality monitoring.

Technical certification

The AQT-SE is designed to meet medical device manufacturing standards, including compliance with relevant ISO (e.g. ISO 13485) and CE certification. All systems for safety, laser emission control, cleanliness, and traceability are incorporated. Components are validated to ensure biocompatibility, repeatability, and documented process control.

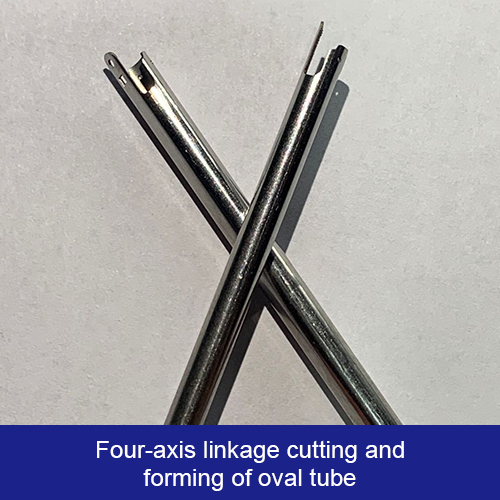

Sample display

Processing Materials:

- 304 Stainless Steel

- Biocompatibility: Low risk of allergic reactions or toxicity, ideal for direct tissue contact in medical procedures.

- Mechanical Properties: High tensile strength (approximately 505 MPa) and elongation (up to 40%), providing flexibility without brittleness.

- Surface Finish: Laser-machined for smooth, burr-free edges, reducing the potential for tissue trauma or contamination.

- Thermal Stability: Maintains integrity across a wide temperature range, suitable for sterilization processes like autoclaving.

- 316L Stainless Steel

- Ni-Ti Alloys

- L605 Alloy

- Aluminum (Al), Copper (Gu), Lithium (Li), Magnesium (Mg), Iron (Fe)

- Aluminum Alloys are lightweight, medical-grade materials valued for their excellent corrosion resistance and high strength-to-weight ratio. With tensile strength typically ranging from 200–600 MPa and good ductility, they offer durability for medical and industrial applications. Their biocompatibility supports use in non-implantable devices and components. Laser-machined for smooth, burr-free surfaces, they minimize contamination risks and ensure compatibility with sterilization processes.

- Magnesium, a lightweight (1.74 g/cm³) and biodegradable metal, is ideal for temporary medical implants like stents and orthopedic screws. Alloys such as WE43 or JDBM offer tensile strength (200–420 MPa) and controlled degradation (6–24 months), safely dissolving into non-toxic byproducts (Mg²⁺ ions). Its biocompatibility (ISO 10993) and ability to support tissue regeneration make it suitable for cardiovascular and bone repair applications. Magnesium’s elastic modulus closely matches bone, minimizing stress shielding in orthopedic uses.

- Lithium (Li): A lightweight, highly reactive metal used in medical devices like batteries for implants. Its high energy density and biocompatibility make it ideal for powering pacemakers and neurostimulators.

- Copper (Cu): A conductive, antimicrobial metal used in medical equipment and coatings. Its excellent electrical conductivity and natural resistance to bacteria enhance device functionality and hygiene.

- Iron (Fe): A strong, durable metal used in some surgical instruments and structural components. Its high strength and cost-effectiveness make it suitable for non-implantable medical tools.

Medical-grade SUS304 stainless steel (austenitic chromium-nickel alloy), offering excellent corrosion resistance and mechanical properties.

316L Stainless Steel is a medical-grade austenitic chromium-nickel alloy renowned for its excellent corrosion resistance and biocompatibility. With a tensile strength of approximately 485–550 MPa and elongation up to 40%, it offers durability and flexibility without brittleness. Its low carbon content enhances weldability and resistance to intergranular corrosion, making it ideal for medical implants and instruments. Laser-machined for smooth, burr-free surfaces, it minimizes tissue irritation in sensitive applications.

Nitinol (NiTi), a nickel-titanium alloy, is renowned for its superelasticity and shape memory, making it a game-changer in medical applications. With a tensile strength of up to 1200 MPa and elastic modulus of 40–75 GPa, nitinol excels in demanding environments.

Cobalt-Chromium Alloys (L605) are medical-grade materials valued for their exceptional strength, corrosion resistance, and biocompatibility. With tensile strength ranging from 800–1500 MPa and hardness of 300–550 HV, they ensure durability in demanding medical applications. Ideal for implants and surgical tools, they support direct tissue contact with minimal reaction. Laser-machined surfaces provide smooth, burr-free finishes, enhancing performance in sensitive procedures.

Clamping Systems:

- Precision D-Type Collets

- ER Series Collets

- Three-Jaw Chucks

Laser Specifications:

- Fiber-Optic Laser

- Wavelength: 1030~1070nm±10nm

- Power Options: 200W, 250W, 300W, 500W, 1000W, QCW150W

Scope of Use

- Endoscopes:

- Rigid Endoscopes

- Standard Endoscopes

- Surgical Instruments:

- Ultrasonic Knives

- Surgical Staplers

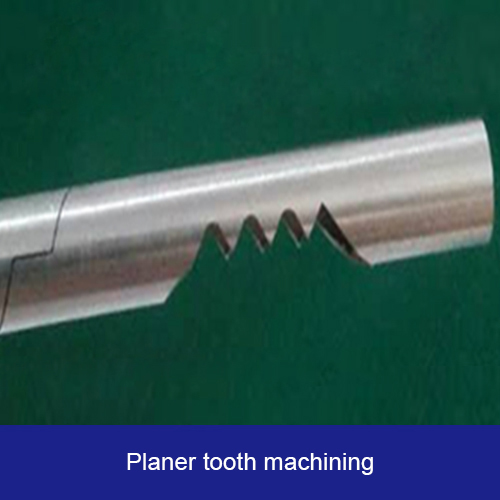

- Soft Drills, Planers, Puncture Needles, Nasal Drills

Processing Capabilities

- Laser Cutting, Drilling, and Grooving

- Centripetal, Vertical, and Compound Openings for Equal Diameter and Reducer Tubes

- Seam Width: 18~30 μm

- High Accuracy: ≤ ±10 μm

Industries Served

- Medical and Industrial Surgical Equipment Manufacturing

Performance and Efficiency

- Maximum Operating Speeds:

- X1-Axis: 300 mm/s

- X2-Axis: 100 mm/s

- Y-Axis: 50 mm/s

- Z-Axis: 50 mm/s

- θ-Axis: 600 rpm

Versatility

- Machining Wall Thickness: 0~2.0 ± 0.02 mm

- Pipe Processing Range:

- Φ0.3~Φ7.5 mm

- Φ1.0~Φ16.0 ± 0.02 mm

- Plane Processing Range: 200 mm x 100 mm

- Tube Blank Length: <2.5 m (customizable for longer lengths)

Flexibility and Customization

- Continuous Automatic Feeding Processing with Auto Loading/Unloading

- Compatible File Formats: DXF, DWG, STP, IGS

- Supports 2D, 2.5D, and 3D CAM Software for Precision Micromachining

Certified Quality

- ISO9001, ISO13485 Certifications

User-Friendly Design

- Optional Machine Vision System for Real-Time Monitoring

- Ergonomic and Intuitive Interface for Easy Operation

- Adaptive Shape Tolerance for Thin-Walled Tubes